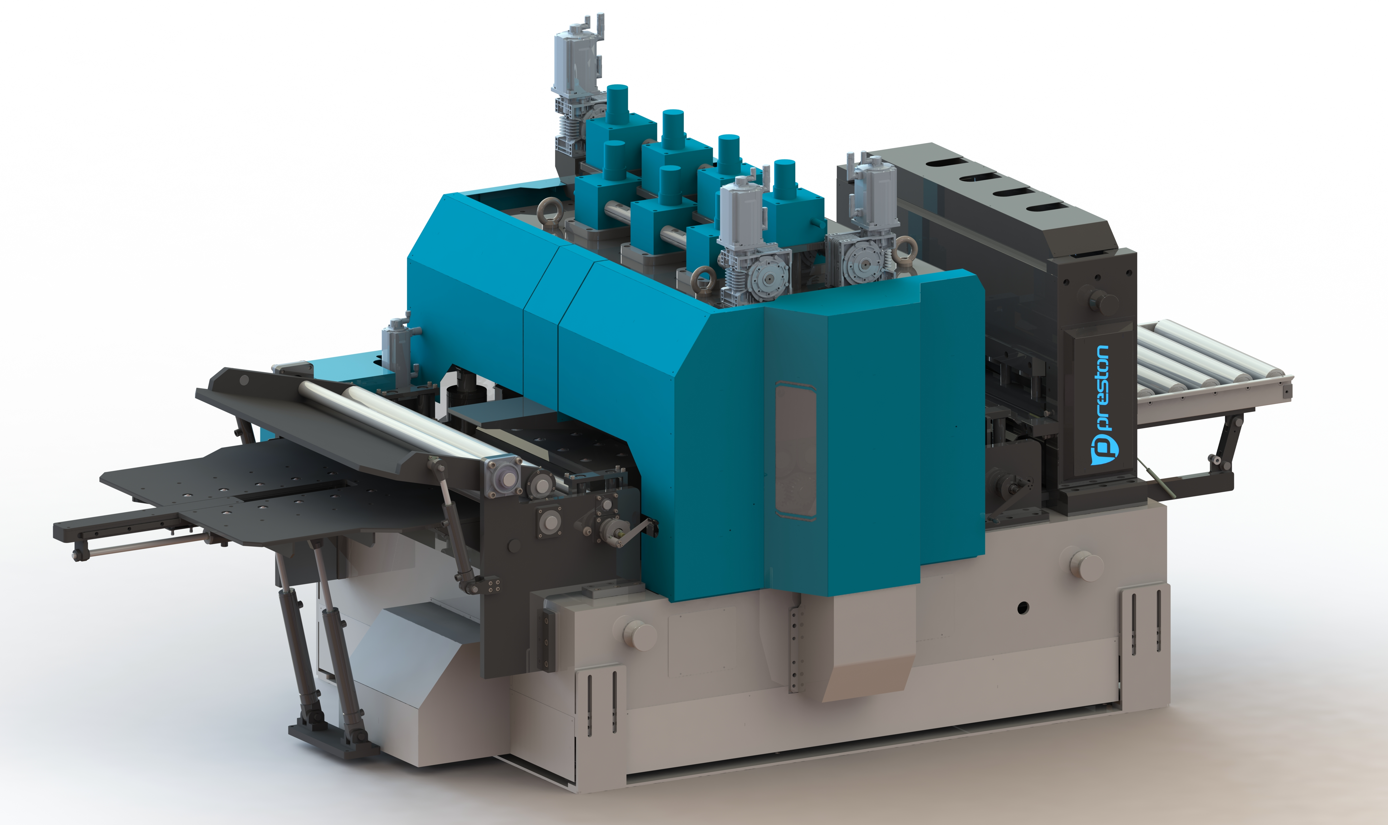

COMPACT FEEDERS

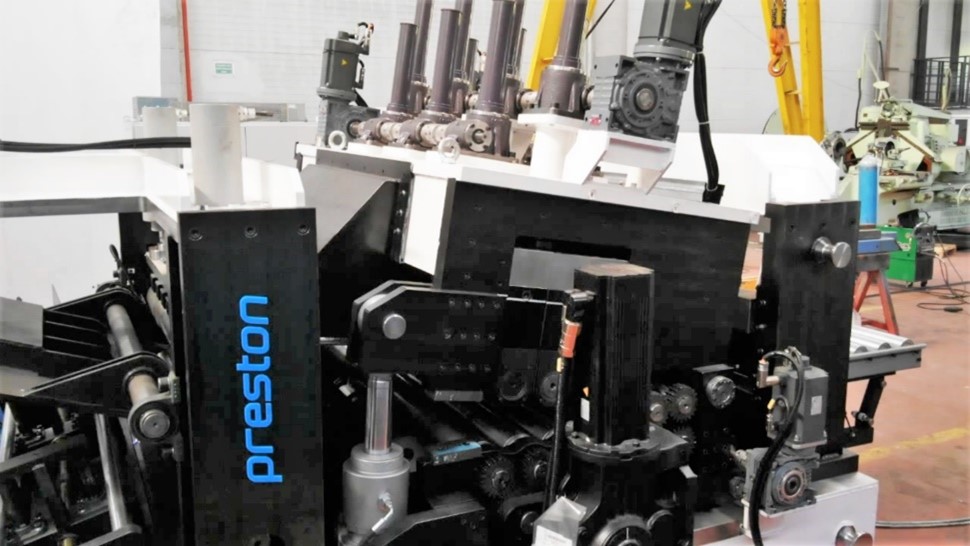

The straightener and the feeder are together. The straightener consists of hydraulic lead in devices, pinch rollers, lower and upper assemblies with back-up rollers, and feeder roller pair. The upper jaw group is opened hydraulically from the inlet side and provides convenience in the coil start end inlet. In addition, there is the option of allowing the sheet to be positioned by the mould pilots during pressing. There are guillotine scissors at the exit side of the straightener.

Standard and Optional Features

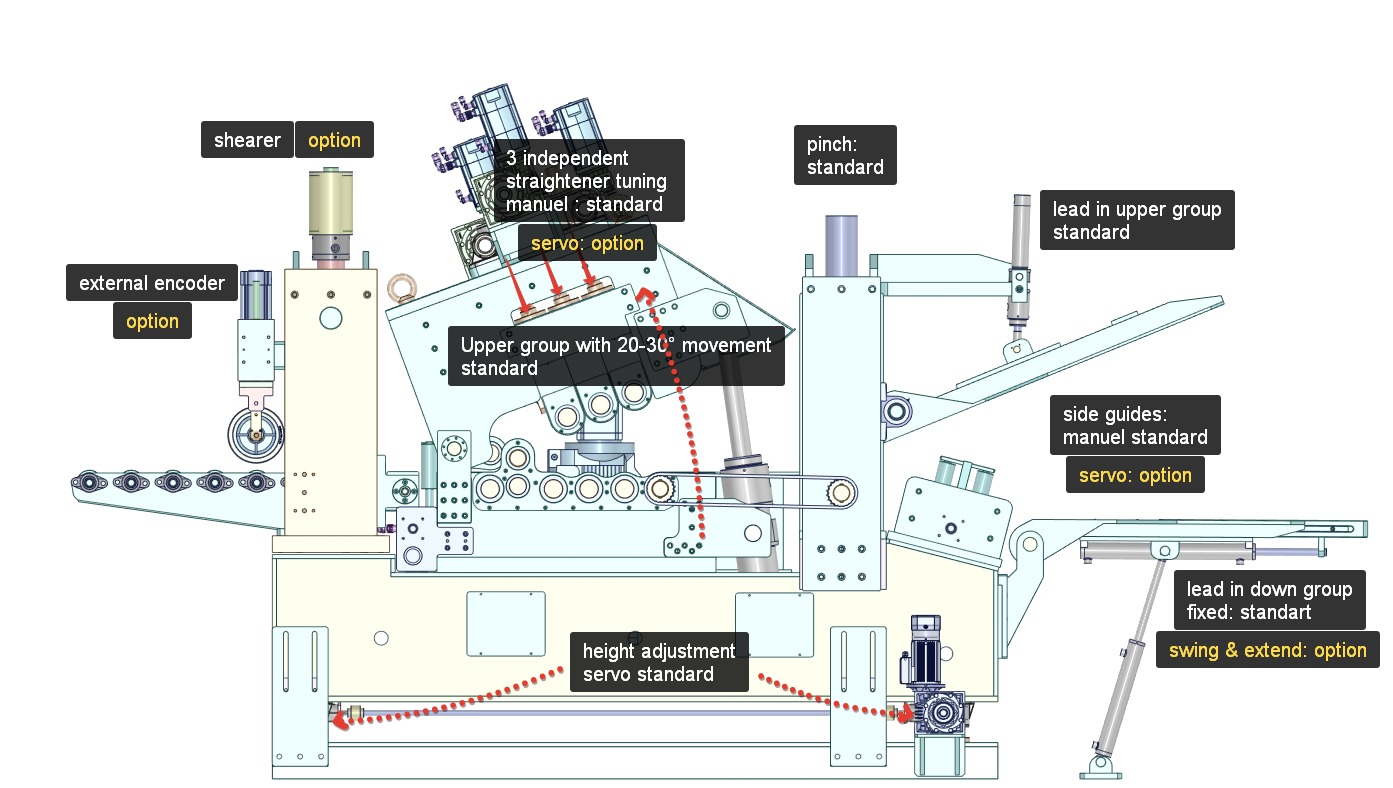

Standard components and specifications are:

1) Two pinch rollers at the entrance

2) 4 rollers at the bottom 3 at the top for dtraightening

3) support rollers behind the straightening rollers

4) Manual side guides at the entrance

5) Manual side guides at exit

6) Three independent manually controlled straightener tuning wheel

7) Openable top group

8) Height adjustment controllable from the operator

9) Optional components and features include:

10) The side guides at the entrance and exit should be servo adjusted

11) Straightener tuning with servo motors

12) Servo controlled side guides adjustment

13) External encoder

14) Handwheel

Control console

Control console with manual control button and 9” touch control panel and optionally handwheel can be added.

The manual buttons are:

1) Unrolling top press up and down rotary button

2) Unrolling rear support up and down rotary button

3) Chuck opening and closing buttons

4) Unroll and rewind rotary button

5) Lead in wings control buttons

6) Pinch roller control buttons

Openable top

The upper group can be opened 20° or 30° depending on the machine size. This feature provides convenience in initial adjustment and maintenance.

The cylinders that move the assembly are hydraulic. If pilotage is desired, the same hydraulic cylinders are used for pilotage.

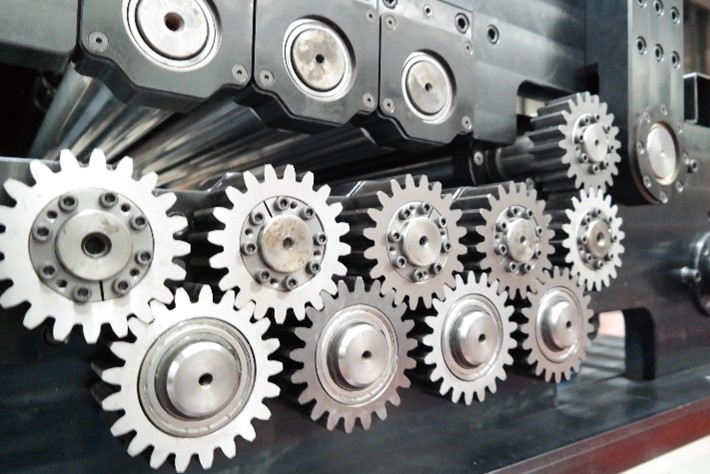

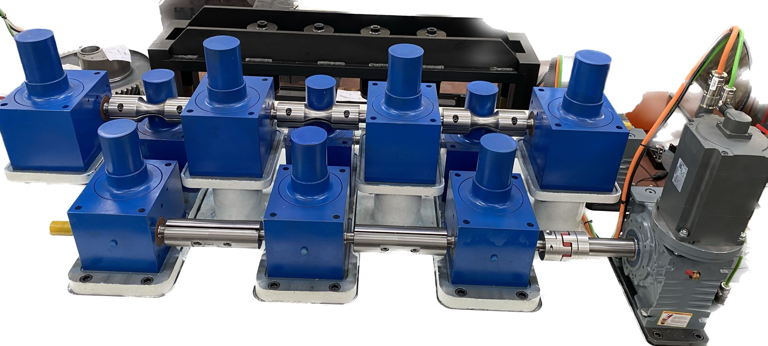

Gear system

To the extent that cylinder diameters and transferred moments allow, a direct gear transmission system is used. Otherwise, the movement is transferred by propeller shafts from a distributor gearbox to each cylinder.

The gears are manufactured from high-quality materials and profile grinding is applied to each gear.

Optional: Servo Driven Straightener Adjustment

The rectification setting is manual as standard. Optionally, the servo motor is added and becomes adjustable from the control panel.

Optional: Servo Driven Side Guides

The adjustment of the side guides in the straightener is manual as standard. Optionally, the servo motor is added and becomes adjustable from the control panel.

Optional: Handwheel

The handwheel and drive servo motor are controlled manually and precisely. Useful when the control panel is far from the mould and control is difficult in mould setting setups.

English

English

Türkçe

Türkçe