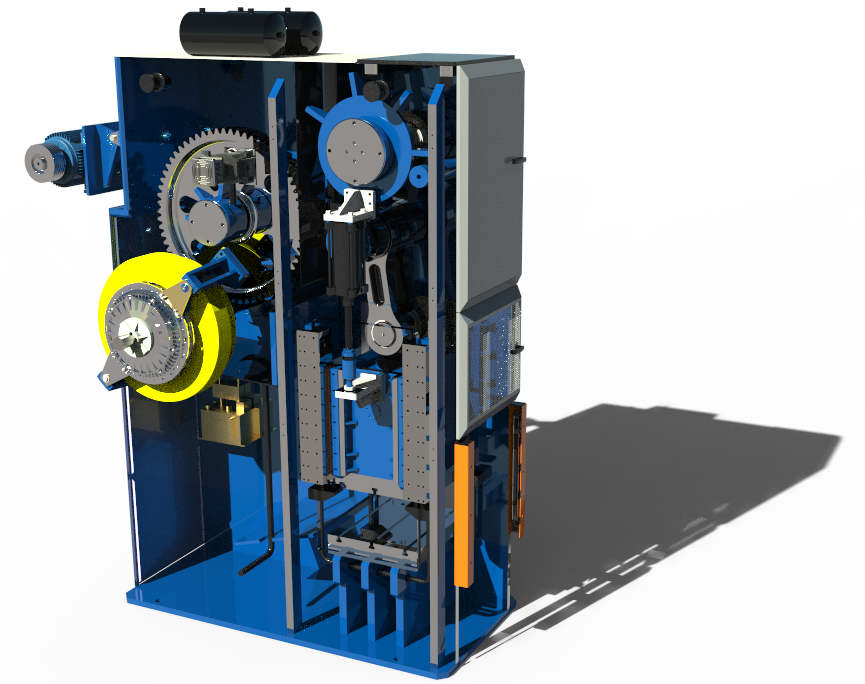

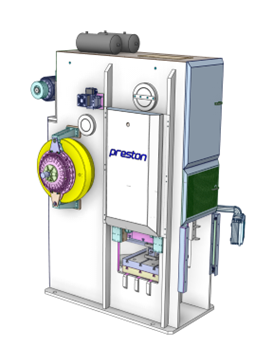

Type D Knuckle Joint Press

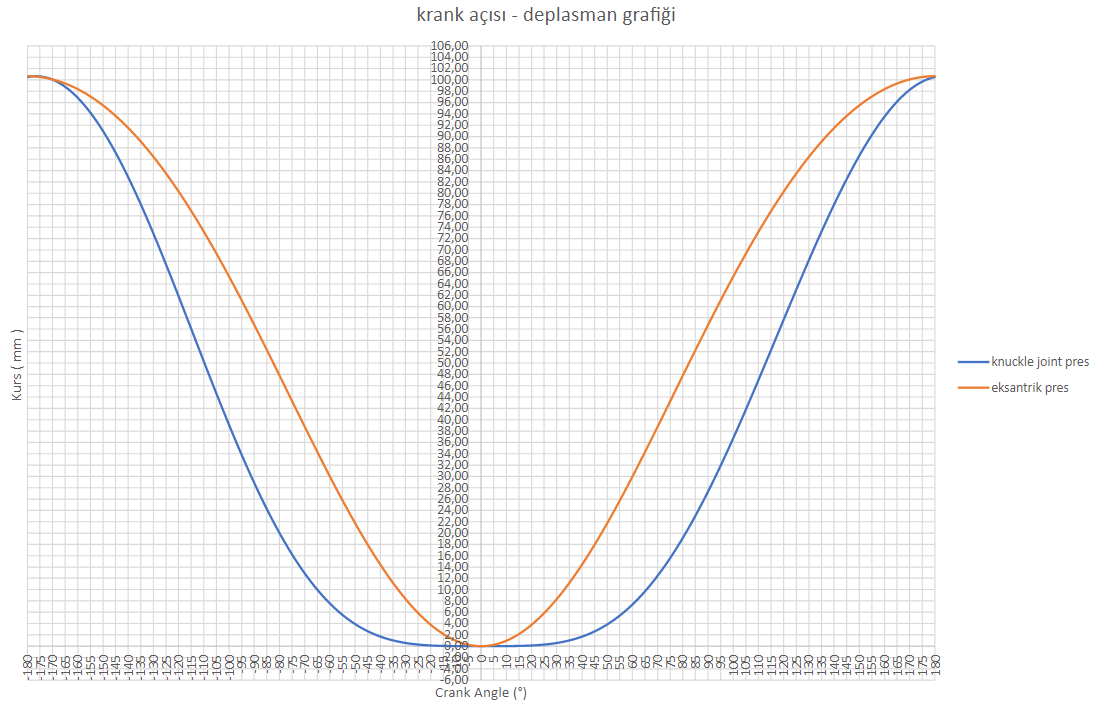

In operations where the displacement-tonnage performance of eccentric presses and link drive presses is not sufficient, it is suitable for slow but high force operations in the lower stroke area.

We produce link drive presses in two connecting rods and four connecting rod configurations.

In industrial standards, PLC, operator panel, cam case, clutch brake valve, clutch brake, encoder and light barriers are selected from globally accepted brands.

Our presses are PLC controlled. We use safety PLC or safety modules in accordance with 2006/42/EC regulation. Depending on the size of the press, we use 9” or 12” rotary console operator panels.

Prescription-based press speed adjustment and regulation adjustment can be made with the encoder from the operator panel.

We manufacture our presses with fixed or mobile plate and cushioning according to your request.

Our gears are zero-gap herringbone gears.

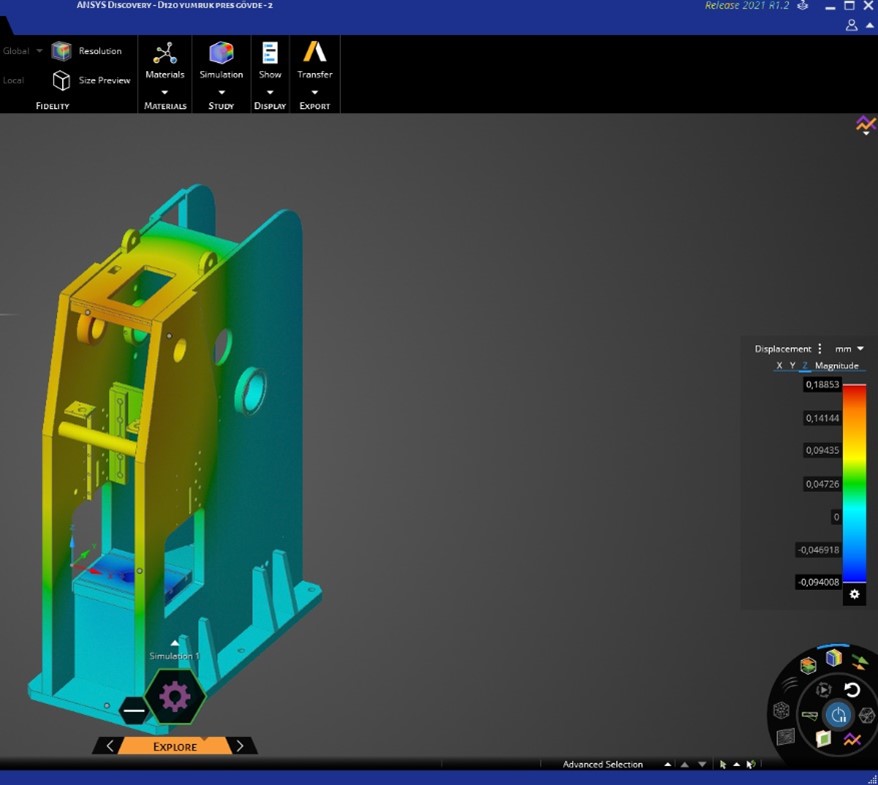

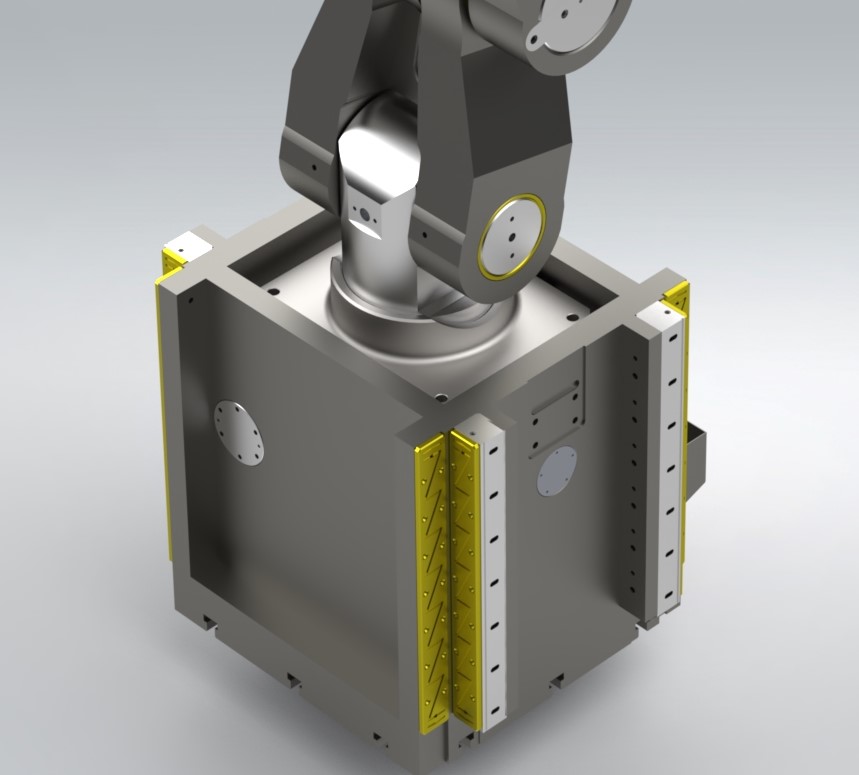

Body Structure

Mono-block body is preferred in D-type presses.

We make our designs by considering the maximum deflection 0.12 mm/m.

The side clearance is determined by the width of the roll to be fed.

No press pit is required.

Knuckle joinr presses are designed for slow but high force operations in the lower stroke zone, so they can be used for printing, extrusion, sizing, embossing. This type of press is ideal for shaping operations that require precise tolerance.

As you get closer to BDC, the ram speed is very low. This low staple input rate provides sufficient time for the plastic flow of the material during the critical cold forming zone.

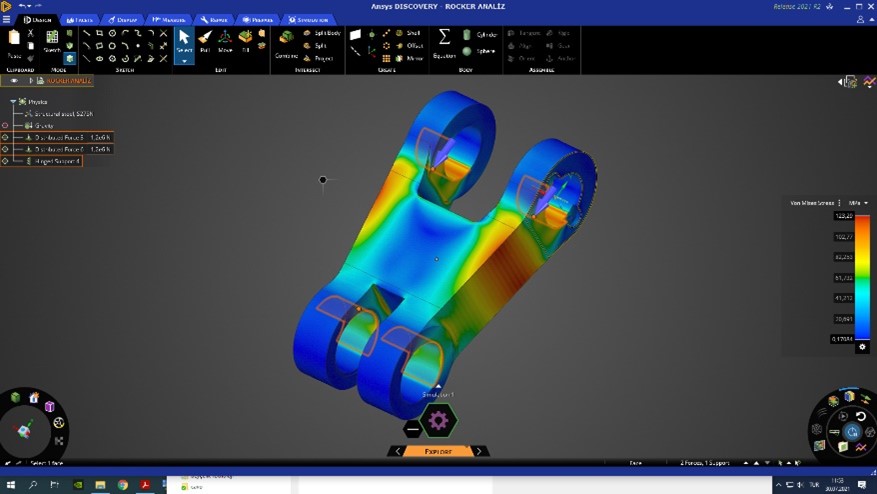

Body design and Manufacturing

Body design is analyzed with Ansys finite element software. In the analysis, we maintain design improvements until we achieve an infinite fatigue life.

We report the results obtained and maintain them by documenting them.

The body is obtained by welding St52-3 quality plates. Welding is performed by certified welders using SG3 welding wire.

After welding, the body is placed in the furnace and subjected to stress relieving process.

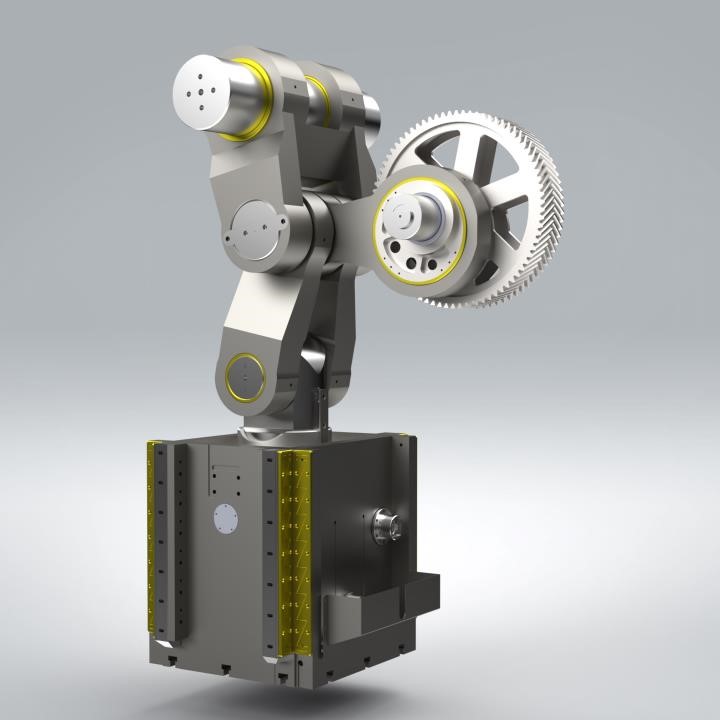

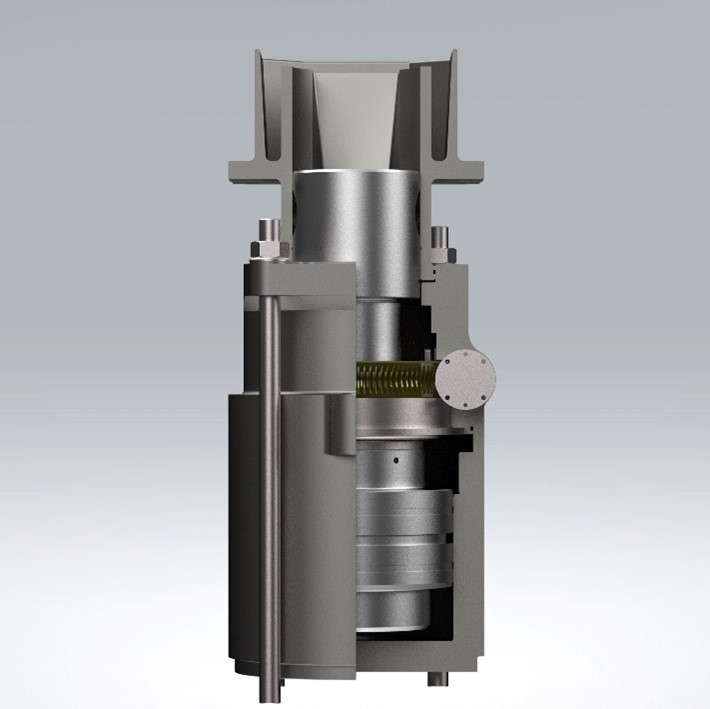

Kinematics

During the process, the parameters of velocity, position, and acceleration are optimized within the limits allowed by the mechanism to properly direct the flow occurring in the material.

While aiming the most appropriate movement curve for the process, it is ensured that the forces to be applied to the press limbs and bearings are kept to a minimum.

Mechanism design

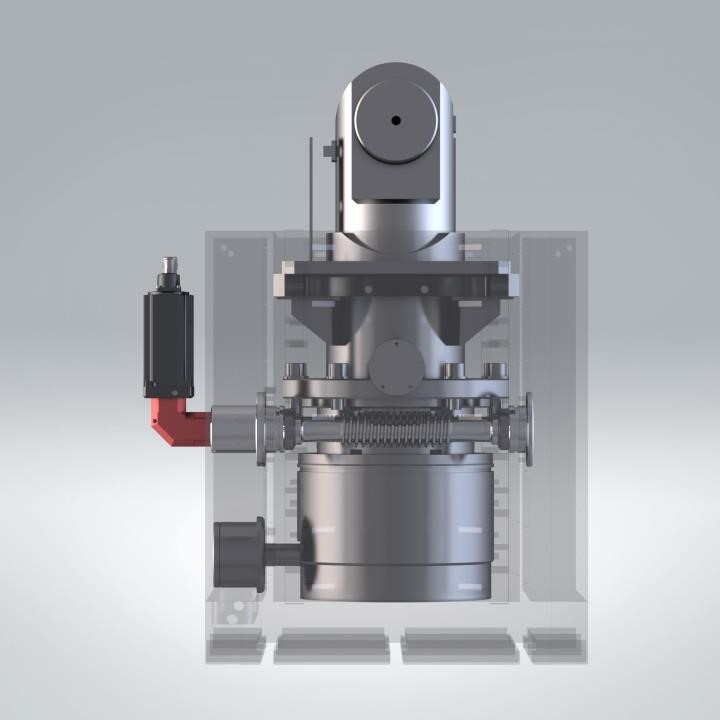

Knuckle-joint mechanism is used in our D-type presses.

The articulated press is ideal for the production of high-precision parts. Suitable for cutting, tearing, forging operations as it quickly discharges energy to the workpiece at the end point. Due to its high surface quality and accuracy. These cold-formed parts are in increasing demand.

Power Train Design

In our designs, we use the finite element method to estimate how the powertrain behaves. We use ANSYS software for these analyzes we perform in the computer environment.

ANSYS, one of the modern simulation software, contains the finite element method on its basis. It helps us find the weakest point in our designs and make parameter optimization.

Slide Guiding

The ram is guided on the columns from 8 surfaces.

Each plate is precisely adjusted and secured by means of bolts in the x and y directions.

Optimized lubrication channel and precision machined bronze bearings work on steel plates.

Clutch & Brake

Pneumatic or hydraulic clutch type is used.

Depending on the press speed, mechanism and operating conditions, the clutch type is selected.

The required clutch and brake size are calculated according to the transmitted power, torque, tonnage and speed information.

Clutch- The brake is controlled by a double valve control system with monitoring, three-way safety. It is vitally important for occupational safety.

Shut Height Adjustment and Overload Protection

The shut height adjustment is achieved by the movement of the nuts working on the thrust bolts.

In our presses, the shut height adjustment and overload protection systems are combined in a single body.

In case of a situation exceeding the press limits during any possible mould failure and mass production, the hydraulic overload valve is activated and possible damage is prevented.

Precise Shut Height Adjustment with Servo Motor

Possibility of 0.1 mm precision with direct servo motor control

D Type Knuckle Joint Press Features

| PresModelNumarası | DK120.0506.150 | DK250.0506.200 | DK400.0607.200 | DK630.0607.200 | DK800.0607.200 | DK1000.0708.200 | DK1250.0810.250 | DK1500.1008.250 |

|---|---|---|---|---|---|---|---|---|

| Tonaj | 120 ton | 250 ton | 400 ton | 630 ton | 800 ton | 1000 ton | 1250 ton | 1500 ton |

| Anma tonaj yüksekliği | 4 mm | 4 mm | 6 mm | 8 mm | 8 mm | 8 mm | 8 mm | 8 mm |

| Tabla ölçüleri | 500 x 600 mm | 500 x 600 mm | 550 x 660 mm | 600 x 700 mm | 600 x 700 mm | 700 x 800 mm | 800 x 1000 mm | 1000 x 800 mm |

| Kurs | 150 mm | 150/200 mm | 150/200 mm | 150/200 mm | 200 mm | 200 mm | 250 mm | 250 mm |

| Pres hızı | 20-100 spm | 20-100 spm | 20-80 spm | 20-80 spm | 15-60 spm | 15-40 spm | 15-40 spm | 15-40 spm |

| Maks. kalıp bağlama yüksekliği (SDAU) | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm | 500 mm | 500 mm | 600 mm |

| Reglaj | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm |

| Tonaj anma ölçüsü | 4 mm | 4 mm | 6 mm | 6 mm | 8 mm | 8 mm | 8 mm | 8 mm |

| Alt plaka kalınlığı | 100 mm | 100 mm | 120 mm | 150 mm | 180 mm | 180 mm | 200 mm | 250 mm |

| Hidrolik sigorta (HOLP) | var | var | var | var | var | var | var | var |

| Mobil tabla | yok | yok | yok | yok | yok | yok | yok | yok |

| Kavrama fren | Desch / Ompi | Desch / Ompi | Desch / Ompi | Desch / Ompi | Desch / Ompi | Desch / Ompi | Desch / Ompi | Desch / Ompi |

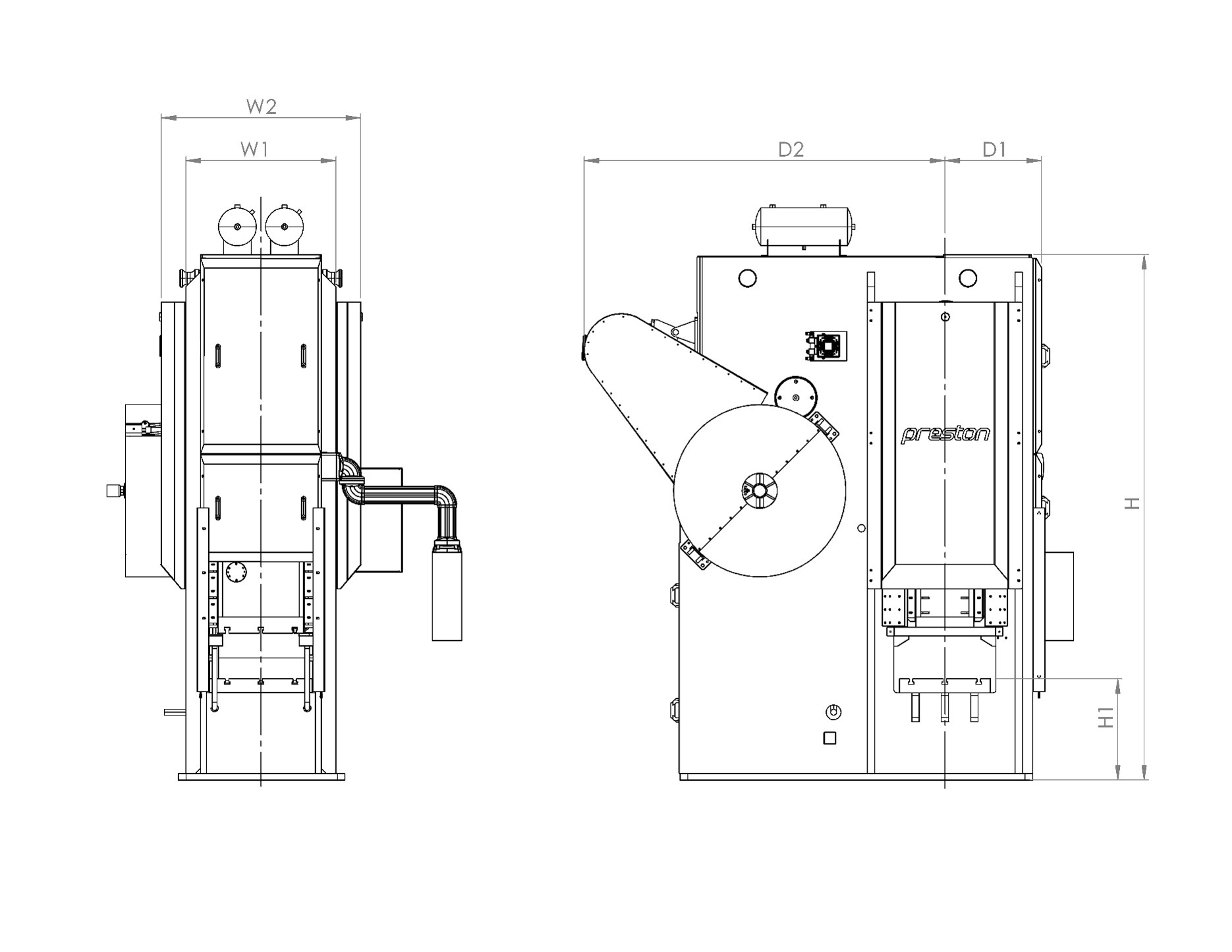

D Type Knuckle Joint Press Dimensions

| Presler | PDK120.0506.150 | PDK250.0506.200 | PDK400.0607.200 | PDK630.0607.200 | PDK800.0607.200 | PDK1000.0708.200 | PDK1250.0810.250 | PDK1500.1008.250 |

|---|---|---|---|---|---|---|---|---|

| H | 3600 mm | 3650 mm | 4150 mm | 4650 mm | 4850 mm | 5650 mm | 6600 mm | 7100 mm |

| H1 | 700 mm | 700 mm | 820 mm | 1000 mm | 1050 mm | 1300 mm | 1470 mm | 2030 mm |

| W1 | 1050 mm | 1150 mm | 1400 mm | 1750 mm | 1750 mm | 1970 mm | 2300 mm | 3200 mm |

| W2 | 1400 mm | 1500 mm | 1780 mm | 2050 mm | 2080 mm | 2350 mm | 2680 mm | 3580 mm |

| D1 | 700 mm | 800 mm | 850 mm | 850 mm | 950 mm | 950 mm | 1050 mm | 1150 mm |

| D2 | 2500 mm | 2500 mm | 2650 mm | 3200 mm | 3350 mm | 3700 mm | 4400 mm | 4900 mm |

English

English

Türkçe

Türkçe