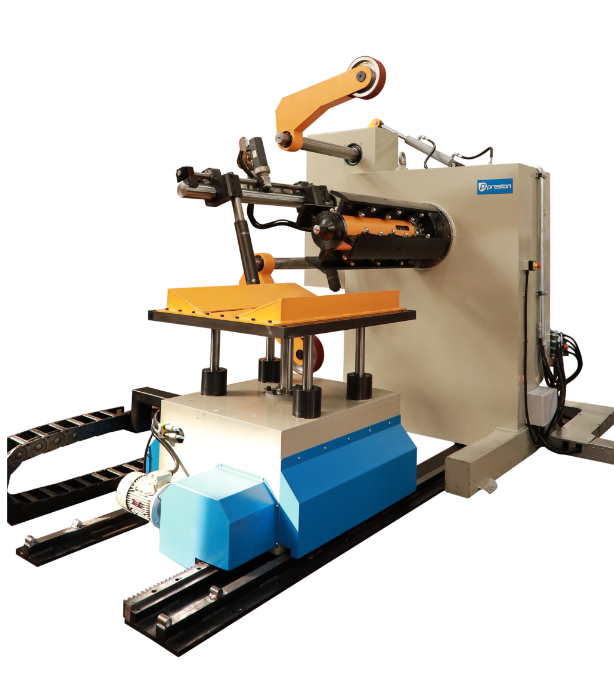

Decoiler

Our product range covers all your needs up to 20 tons of weight, 1600 mm wide

The coil car is moved by rack pinion.

It has a hydraulically activated chuck.

Equipped with a disc is brake.

It has hydraulic upper thrust and rear support arms.

The top print offers the option of a driven drum.

Standard and Optional Features

The standard components are:

1) Motorized horizontal moving coil car

2) Coil lifting in coil car

3) Hydraulically controlled chuck

4) Upper arm

5) Rear support arm

6) Disc brake

7) Measurement with laser

The optional components are:

8) Hyromotor driven motor on upper arm

9) Coil side supports with servo adjustment

10) Handwheel

Control console

Control console with manual control button and 9” touch control panel and optionally handwheel can be added.

The manual buttons are:

1) Unrolling top press up and down rotary button

2) Unrolling rear support up and down rotary button

3) Chuck opening and closing buttons

4) Unroll and rewind rotary button

5) Lead in wings control buttons

6) Pinch roller control buttons

Chuck

Mandren opening and closing movement is performed with an hydraulic cylinder. Scissor mechanism is used up to 5 tons of roll weight, then cam mechanism is used. Works between 480 and 540 mm as standard. Diameters can be changed according to customer demand. Designed and manufactured in such a way that the deflection at the end of the mirror does not exceed 3 mm when the coil is loaded and centered.

Servo Driven Coil Side Supports

The servo motor controlled coil side support arms are moved by a hydraulic cylinder, such as the upper thrust arm and the rear support arm, and aligned with the coil.

It approaches the coil from both sides by means of screw shafts operating in the opposite direction.

A "side support unit" is provided as standard in the opener. The latter is priced as an option if desired.

Coil Car

The movement of the coil car towards the opener is provided by an electric motor placed in the car. Rack and pinion gear is used for position accuracy. The electric motor is driven by an inverter. It slows down as it approaches the target and allows it to be positioned in the correct position.

Caliper Disc Brake

The decoiler has a rotating disc mounted on the mandren. The amount of sagging of the opened sheet is continuously measured from the bottom. Decoiler speed and disc brakes are controlled by taking this precaution into account. This ensures that there is always enough material in front of the feeder

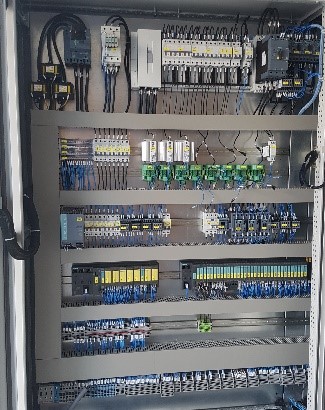

Control System

PLC & Motion Control : Siemens

• PLC: Siemens S7-1500 series

• HMI: Siemens KPT900

• Servo motor drivers: Siemens

• AC motor inverter: Sew, Siemens ABB or equivalent

Optional: Handwheel

The handwheel and drive servo motor are controlled manually and precisely.

Useful when the control panel is far from the press table and control is difficult in tool setting setups.

English

English

Türkçe

Türkçe